|

Sneak Preview

SBIG's New STX Series

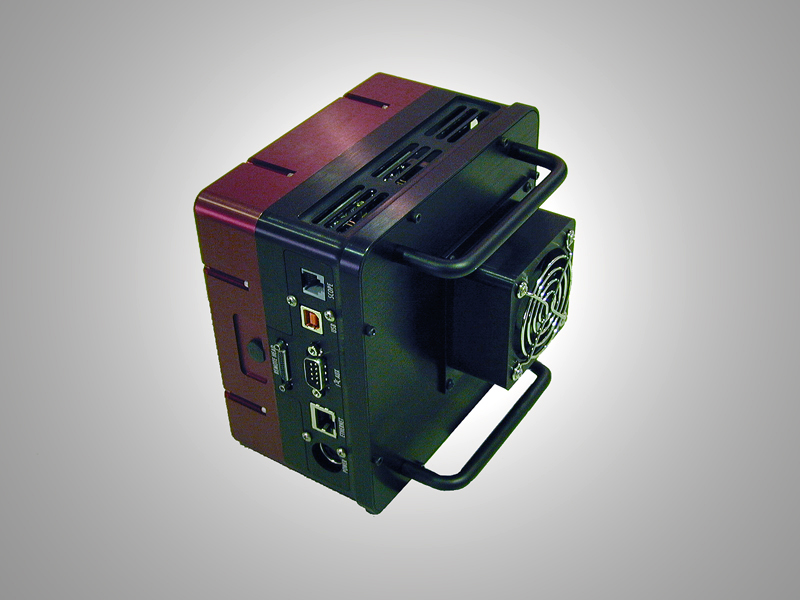

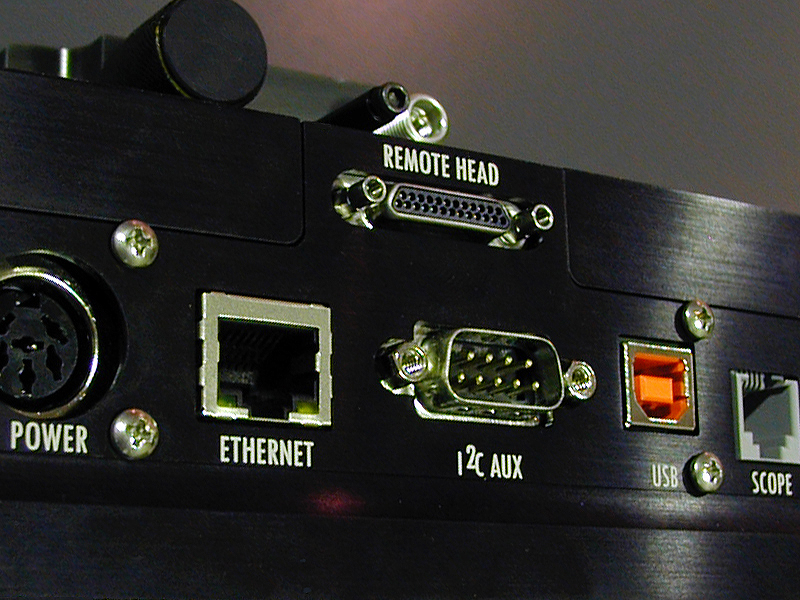

The photo's below are of the first prototype STX

camera.

The description of features and any specifications are preliminary.

|

|

|

|

|

Support for the following CCDs are being considered for the STX series: |

|||||

CCD |

Pixels |

Array |

Pixel |

Mono / Color |

Notes |

KAF-1001 |

1 Megapixel |

1024 x 1024 |

24u |

Mono |

Full Frame, large pixels |

KAI-4022 |

4.2 Megapixels |

2048 x 2048 |

7.4u |

Mono or Color |

New CCD, 25% lower noise |

KAF-6303 |

6.3 Megapixels |

3060 x 2040 |

9u |

Mono |

Full Frame, High QE |

KAF-8300 |

8.3 Megapixels |

3326 x 2504 |

5.4u |

Mono or color |

Full Frame Microlens ABG |

KAF-9000 |

9 Megapixels |

3056 x 3056 |

12u |

Mono |

Full Frame Microlens ABG |

KAI-10100 |

10.1 Megapixels |

3648 x 2760 |

4.75u |

Color |

2x2 Color Binning |

KAI-11002 |

11 Megapixels |

4008 x 2675 |

9u |

Mono or Color |

35mm format |

KAI-16000 |

16 Megapixels |

4872 x 3248 |

7.4u |

Mono or color |

35mm format |

KAF-16803 |

16 Megapixels |

4096 x 4096 |

9u |

Mono |

Full Frame Microlens ABG |

CCD42-40 |

4 Megapixels |

2048 x 2048 |

13.5u |

Mono |

Back illuminated High QE |

CCD47-10 |

1 Megapixels |

1056 x 1027 |

13u |

Mono |

Back illuminated High QE |

CCD42-00 |

262,144 Pixels |

512 x 512 |

24u |

Mono |

Back illuminated High QE |

USB 2.0 and Ethernet on each camera

12VDC Operation (Operates from 9 - 14VDC)

Full Frame Image Buffer

Multiple A/D Channels

Image and Guide While Downloading

Internal and External Self-Guiding (with Remote Head)

Simultaneous Dual CCD Guiding

Differential Guiding (patent pending)

Continuous Guiding During Autograb

Adaptive Optics Control with Internal or External Guider

-50 degrees C Delta Cooling with Air Only

Water Cooling Ready

Even-illumination Mechanical Shutter

Gas Purge Valve on CCD Chamber

User Rechargeable Desiccant Plug

Variable Speed Fan Control

Focus Mechanism for Tracking CCD

Opto-isolated Relays for Telescope Control

Tracking Relay LED Indicators

Power Management LED Indicators

New Guiding Techniques for the STX

It is well known that the advantage of easier guiding through a separate guide scopes is often limited by differential deflection of the guide scope relative to the main optical axis due to mechanical flexure or shifting of the mirror in the main OTA. This difficulty is addressed with two new guiding techniques developed by SBIG and implemented in the STX series cameras: Simultaneous Guiding and Differential Guiding.

Built-in Guiding CCD with Adjustable Focus: Simple self-guiding and control of our Adaptive Optics accessory using just the internal tracking CCD will be a standard feature. The guiding CCD in the STX cameras will be a new KAI-340 CCD with 640 x 480 pixels at 7.4u. As the imaging CCDs get larger, the guiding CCD gets pushed farther away from the center of the optical axis. Depending on the nature of the optical system, this can cause the image on the guiding CCD to be slightly out of focus when the image on the main CCD is in focus. To address this, the new STX cameras will have a user accessible adjustment for changing the focal point of the on-board guiding CCD.

Optional Remote Guide Head: A Remote Guide Head will be optional for the STX cameras. Self-guiding through a separate guide scope or off-axis guider, and control of the Adaptive Optics accessory, can be done using the Remote Guide Head instead of or in addition to the on-board guiding CCD. The same KAI-340 CCD will be used in the new Remote Guide Head made for the STX series cameras.

Simultaneous Guiding: The external guide head will not only continue to guide while the imaging CCD is downloading an image, but it can be operated simultaneously with the on-board guiding CCD. This allows a unique type of guiding through a separate guide scope that will correct for differential deflection by using the external guider to make fast corrections while the on-board guider makes slow corrections. Differential deflection tends to occur over a longer period of time than drive errors, typically minutes vs. seconds. A long exposure taken with the built-in guider is capable of reaching dim stars without searching, even through narrowband filters, and a long exposure with slow corrections with this on-board guider will correct for the slow differential deflection typically experienced with a separate guide scope. In the mean time, the Remote Guide Head can simultaneously make fast corrections using the brighter stars easily found with a short refractor mounted piggy back to the main OTA. This technique, developed independently, is similar to the technique employed successfully by Italian amateur Filippo Ciferri using two separate cameras for which he deserves full credit. With the STX, however, a single camera and remote head will perform both the fast and slow guiding, as well as the imaging, all at the same time, using a single instance of the control software and only one connection to a computer.

Differential Guiding: SBIG has a patent pending on a new guiding technique using an artificial guide star. Although artificial stars are used in a variety of techniques on professional telescopes, the SBIG technique is somewhat different and easy to implement on amateur scopes. An artificial star is created near the focal plane of the imaging CCD and an image of this star is retro-reflected into a separate guide scope. By using one real star in the FOV of the guide scope and the artificial star image reflected from the main scope, the difference in separation caused by telescope pointing errors is used to make the corrections to the telescope drive. There is no problem with differential deflection and a single CCD external guider can be used to monitor both the real and artificial guide stars. The artificial star image is not seen by the imaging CCD.

Some Design Features of the STX

USB 2.0 and Ethernet: Both USB 2.0 and Ethernet will be available on each STX camera. The user will not have to choose the interface at the time of purchase. The STX cameras will have the same convenient I2C AUX port that we use on the ST and STL cameras for power and control of accessories such as filter wheels and Adaptive Optics, and will operate from any unregulated 12VDC source.

12VDC Operation: In similar fashion to the STL cameras, the STX will internally regulate a 12VDC supply so that the camera can be connected directly to any unregulated 12VDC source such as a car battery. The camera will have 4 power LEDs that will indicate if the supply voltage drops to 11, 10 or 9 volts and when it is "good." Operation of the camera is possible with a supply voltage of 9.1 to 14 volts DC.

Full Frame Image Buffer: The STX series cameras will have a full frame image buffer for storing image data during download. The STX will be able to image during download process. We are exploring the possibility of using this buffer for pre-processing pixel defects based on a defect map provided by the CCD manufacturer, at the userís direction.

Multiple A/D Channels: Having multiple A/D channels available makes a number of things possible. For instance, the STX cameras will be able to download and guide, or guide with two guiders all at the same time. Guiding can continue uninterrupted using the Remote Head during an autograb sequence, or an automated LRGB sequence, just as it would if you were using a separate camera or autoguider independent the camera.

Improved Cooling: Our engineers have modeled an optimum cooling design for this camera using a large custom pin grid array heat sink mated directly to the hot side of the 2 stage TE cooler to achieve maximum heat dissipation with a single large fan. The STX is designed to achieve a minimum delta of -50 degrees C with air only, and a similar delta with water only.

Water Circulation Ready: While the design is aimed at sufficient cooling without water assist, it is possible to use water instead of air or in addition to air for optimum cooling. Using water instead of air will not require the use of a fan. Chilled water may also be used alone or with the fan for even greater cooling.

Even-illumination Shutter: Starting with the first ST-7 camera, SBIG has incorporated an even-illumination shutter for taking short exposure flat field frames on all self-guiding cameras. However, the rotating disk design becomes rather large with ever increasing CCD sizes. Therefore, a new shutter design will be introduced with the STX series that reduces the overall size and weight of the camera body, while maintaining even illumination on short exposures with large CCDs.

Desiccant + Gas Purge Ports: In order to allow the user the greatest flexibility in the field, and to avoid having to return the camera to the factory in order to purge the CCD chamber with inert gas, we have designed the chamber to accept both a rechargeable desiccant plug similar to our current ST and STL cameras, and a gas purge port for purging the chamber with Argon or other inert gas if desired. The camera is designed to operate normally without the need of inert gas in the CCD chamber, but the option to use such gas will be up to the user.

Focusing Mechanism of Tracking CCD: As CCDs get larger, the tracking CCD is moved farther off-center from the optical axis. This can result in out-of-focus guide stars. In order to compensate for different telescopes and different tracking CCD locations, the built-in guider will have a small, user accessible, focus adjustment for the tracking CCD. Once this is set for a particular camera and scope combination, it will not be necessary to change it.

Opto-isolated Relays for Telescope Control: These isolated relays will not require an external Relay Adapter box or other opto-isolator to work with virtually any telescope mount that accepts autoguider inputs for guiding control.

Tracking Relay LED indicators: This handy set of 4 LEDs will tell you at a glance if the camera is issuing corrections to the mount in +X, -X, +Y or -Y directions during an imaging session.

Adaptive Optics and Filter Wheels: Due to the sizes of some of the planned CCDs, a new AO and Filter Wheel will be designed for the STX cameras. Filters for most of these chips will need to be larger than 1.25". Some need to be larger than 2" or 50mm round.

Development Schedule

This product is not yet available for sale. The prototype will be shown at NEAIC + NEAF in April 2008 following which it will be prepared for FCC certification. We estimate it will take 30 - 60 days to prepare the final prototype for FCC. Certification usually takes about 30 days if it passes the first time, and following successful certification it then takes approximately 4 months to prepare for production. This means that assuming no issues arise that could delay the process our estimate of production beginning in Winter of 2008 is still on target. Any delay in preparing for FCC or any subsequent delay required to obtain FCC certification could add to this estimate. We will post updates as get closer to production. Please note that we do not have any price information at this time and we are not taking orders until after we have received FCC approval, and have determined both pricing and delivery times.