Advanced Telescope Supplies

Australia's Premier CCD and Astro-Imaging Experts

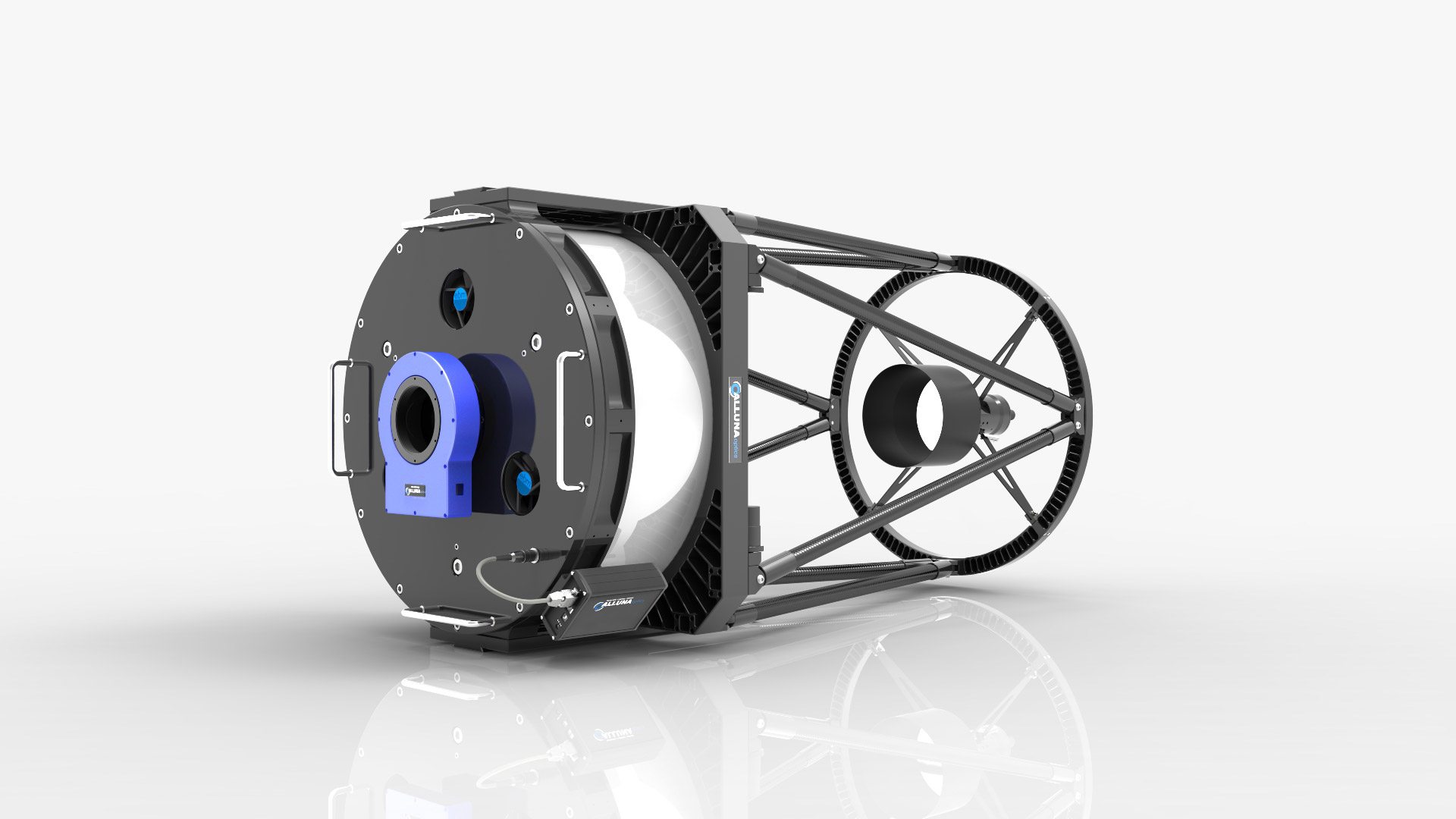

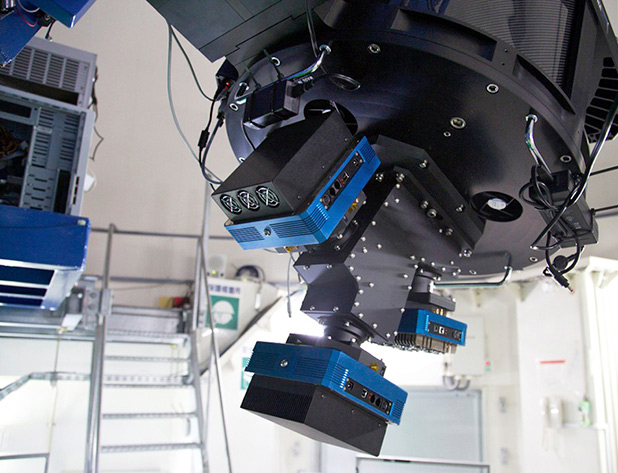

Alluna RC's..... designed for 50 kg instrumentation loads

The design of Alluna telescopes incorporates a complex honeycomb structure milled from solid aluminium. This provides extremely high structural strength and stiffness . As an example, the RC20 is milled from solid aluminium plates with a gross weight of around 340 kg, but only about 40 kg of material remains at the end of the extensive milling operations.

This skilled removal of non-structural metal delivers a 55mm thick honeycombed truss plate, with the stability and twisting rigidity of a 55 mm solid plate. Yet has approximately 9x less mass. This significant reduction in non-structural mass reduces the natural frequency of vibration of the telescope , reduces unnecessary loads on the telescope mounting, reduces the effect of any perturbations and vibration, and enhances image-plane stability. Not suprisingly , this level of engineering design, performance and quality does not come without a cost! Not only must the backplate must not distort under load, but nor should the mounting plate and saddle plates. Other, Ritchey Chretien manufacturers are decidely cheaper as they use thin plates with litte or no loading analysis and thicknesses of a mere 10 to 20 mm to save cost, yet still be left with "dead" or structurally useless weight. As a result they are no-where near as rigid and will sag or bend under load. Alluna Optics virtually stand alone in their ability to withstand a high instrument loads, without the slightest shift of the optical axis, due their excellent design, engineering and precise manufacturing. Alluna telescopes are also ready for a vast array of all secondary optics. For example, the upper mounting plate, which is often used for holding small refractors, is quite capable of holding larger and heavier secondary instruments with few restrictions. Alluna use state-of-the art CAD software and FEA (finite element analysis). This ensures that all parts are optimized for weight, stability and thermal expansion. FEA is an important tool creating Alluna's sublimely crafted instruments.The extensive use of FEA helps to analyse all stresses and loads through modeling and simulation hence optimise their design. If you want to use even larger instrument loads on Alluna telescopes, please contact us. We can liase with Alluna to make engineering modifications based on your requirements and integrate the desired mounts right into the design and manufacturing

|

Above: Solid Aluminium sheets ready for milling

Above: Milling in progress

Above: RC plates machined for low mass yet retain rigidity and stiffness

Above: Engineered without compromise: Alluna RC's |